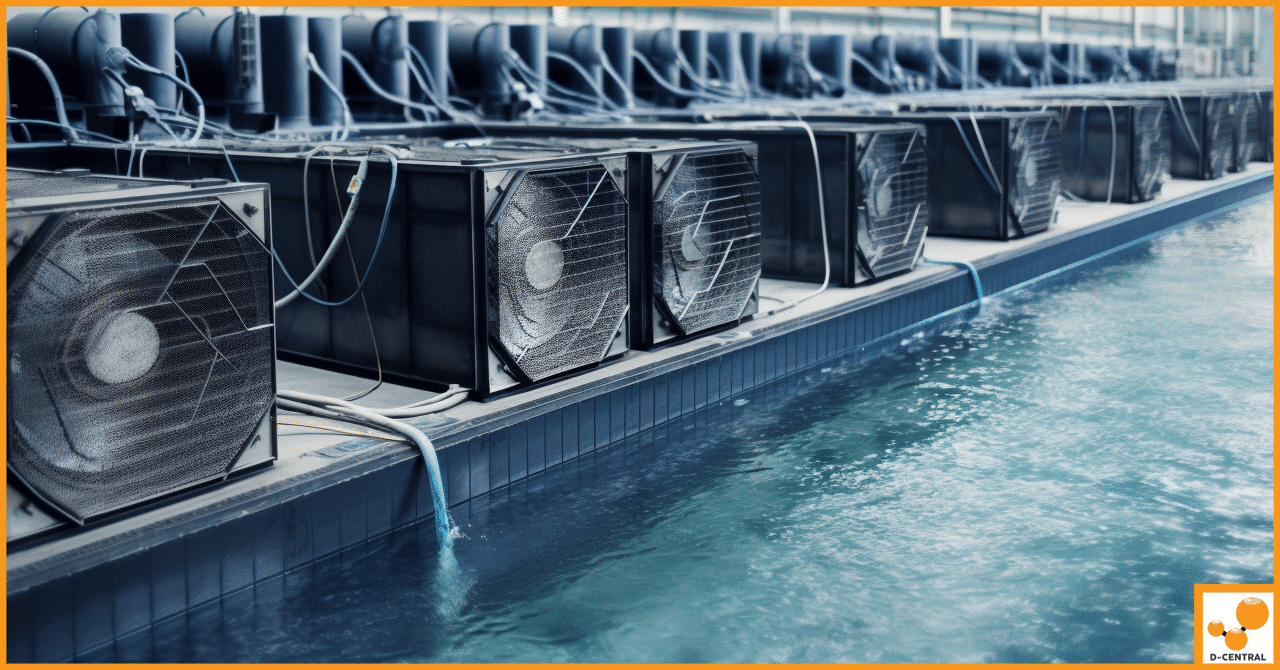

Aquaculture Facilities Can Save Money on Heating Costs with Bitcoin Mining

The aquaculture industry is facing an ongoing challenge of maintaining the optimal temperature for aquatic organisms, which can be a

4479 Desserte Nord Autoroute 440, Laval, QC H7P 6E2

In the dynamic world of cryptocurrency mining, Antminers have emerged as the linchpin of Bitcoin mining operations, setting the gold standard for efficiency and performance. These specialized devices, designed to solve complex cryptographic puzzles, are at the heart of the blockchain technology that underpins Bitcoin. Their unparalleled processing power and energy efficiency have made Antminers indispensable for miners aiming to maximize their returns in the competitive landscape of digital currency mining.

However, the sophistication of Antminers comes with its own set of challenges, particularly when it comes to maintenance and repairs. The intricate electronic components and high-voltage operations inherent in these devices necessitate a profound emphasis on electrical safety. Mishandling or improper repairs can not only lead to costly downtime but also pose significant safety risks to operators.

Enter D-Central Technologies, Canada’s premier ASIC repair center and a beacon of trust and expertise in the Bitcoin mining industry. At D-Central, we understand the critical role that Antminers play in your mining operations, and we are dedicated to ensuring that your equipment runs safely and efficiently. Our team of seasoned experts specializes in providing top-tier Antminer repair services, backed by a deep understanding of the electrical safety protocols essential to handling these sophisticated machines.

With a commitment to excellence, D-Central Technologies stands as a leader in not just repairing but also optimizing your Antminer’s performance. Our bespoke solutions, ranging from silent fans for home mining to custom modifications for enhanced compatibility, are designed with your safety and success in mind. Trust D-Central to keep your Antminers in peak condition, ensuring that your Bitcoin mining endeavours are both profitable and secure.

An Antminer is not just a piece of hardware; it’s the lifeblood of the Bitcoin mining process. Developed by Bitmain, one of the leading manufacturers in the cryptocurrency mining industry, Antminers are specialized devices known as ASICs (Application-Specific Integrated Circuits). These powerful machines are engineered specifically for mining cryptocurrencies like Bitcoin, offering unmatched efficiency and processing power in solving the complex cryptographic puzzles that underpin blockchain technology.

The significance of Antminers in cryptocurrency mining cannot be overstated. They are pivotal in validating transactions and securing the blockchain, a decentralized ledger that records all transactions across a network. By solving these cryptographic challenges, Antminers contribute to the process of “mining,” which not only processes transactions but also generates new bitcoins, rewarding miners for their efforts and investment in the network’s security and integrity.

However, the sophisticated technology and high-performance demands of Antminers come with their own set of challenges, particularly when it comes to maintenance and repairs. Common issues that Antminers may encounter include:

Given the electrical complexity and the high-voltage components involved in these devices, addressing these issues requires not just technical know-how but also a stringent adherence to electrical safety protocols. Mishandling repairs or maintenance can lead to electrical shocks, further damage to the device, or even fire hazards, emphasizing the need for professional expertise and safety-first practices in Antminer repairs. At D-Central Technologies, we prioritize your safety and the optimal performance of your Antminers, ensuring that every repair and maintenance task is conducted with the utmost precision and care.

When it comes to repairing Antminers, electrical safety is paramount. The intricate design and high-power requirements of these devices necessitate a comprehensive approach to safety that encompasses several core principles. Understanding and implementing these pillars of electrical safety can significantly mitigate risks, ensuring both the operator’s safety and the longevity of the Antminer. Here are the foundational elements of electrical safety in Antminer repairs:

Before embarking on any repair, proper preparation is crucial. This includes equipping oneself with the appropriate protective gear. Insulated gloves and rubber-soled shoes are essential to minimize the risk of electrical shocks. Additionally, wearing non-conductive clothing and removing any metal jewelry can further reduce the likelihood of accidental conductivity.

Given the electrical nature of Antminer repairs, the use of insulated tools is non-negotiable. These tools are designed to prevent electricity from flowing through them, offering an added layer of protection against electrical shocks. Whether it’s screwdrivers, pliers, or wire cutters, ensuring that every tool is insulated is a critical safety measure.

One of the first steps in any repair process should be to power down the device completely and disconnect it from any power sources. This eliminates the risk of electrical shocks and prevents any accidental damage to the device’s components during the repair. It’s also important to be mindful of capacitors and other components that might retain charge even after the device is powered off.

A deep understanding of the Antminer’s architecture and electrical systems is essential for safe repairs. This includes familiarity with the device’s schematics, component layout, and potential hazards. Training and experience play a significant role in recognizing and mitigating risks, making it crucial for repair technicians to be well-versed in the specifics of Antminer technology.

The repair environment should be carefully controlled to minimize risks. This means working in a well-lit, dry, and clutter-free space to prevent accidents. Ensuring that the workspace is free from conductive materials and liquids is essential to avoid unintended electrical paths that could lead to shocks or short circuits.

Static electricity can pose a significant risk to the sensitive components of an Antminer. Techniques such as grounding oneself before handling the device’s components can prevent static discharge, which could otherwise damage the electronics. Using anti-static mats or wristbands can also be beneficial in mitigating these risks.

Rushing through repairs can lead to oversights and mistakes that compromise safety. A cautious and methodical approach, where each step is carefully planned and executed, can significantly enhance safety. This includes double-checking connections, verifying that components are correctly installed, and methodically troubleshooting issues without jumping to conclusions.

By adhering to these pillars of electrical safety, individuals and professionals alike can ensure that Antminer repairs are conducted safely and effectively. At D-Central Technologies, these principles guide our approach to every repair, reflecting our commitment to safety, excellence, and the optimal performance of your Bitcoin mining operations.

In the meticulous world of Antminer repairs, the adage “safety first” is not just a guideline; it’s an imperative. The high-powered electrical components within these devices demand a rigorous adherence to safety protocols, starting with the very basics: the gear you wear and the tools you use.

The foundation of safe repair practices begins with what you wear. Rubber-soled shoes stand out as a critical piece of protective gear, offering insulation from electrical shocks that might occur due to inadvertent contact with charged components. These shoes act as a barrier, preventing the flow of electricity through the body, thereby significantly reducing the risk of electrocution.

Equally important is the practice of removing metal jewelry before starting any repair work. Metal, being an excellent conductor of electricity, can easily create an unintended path for electrical current if it comes into contact with live components. This can lead to severe shocks, burns, or even more dire consequences. Rings, bracelets, watches, and necklaces should be removed to eliminate this risk, ensuring that your focus on the task at hand isn’t compromised by avoidable hazards.

When delving into the heart of an Antminer, the tools in your hand are not just instruments of repair; they are guardians of your safety. Insulated tools are designed with non-conductive handles that prevent electricity from passing through, offering an essential layer of protection between you and the electrical currents within the device. Whether it’s a screwdriver, pliers, or wire strippers, ensuring that every tool is insulated is a fundamental safety measure that cannot be overlooked.

Professionals in the field of Antminer repairs often share their experiences, underscoring the importance of these safety practices. For instance, Lisa, an Antminer repair specialist from Montreal, recounts a close call that reinforced her commitment to safety gear. “There was a moment when I accidentally brushed against a live component. Thankfully, my rubber-soled shoes and the absence of any metal jewelry meant that I walked away unscathed. It was a stark reminder of why these precautions are non-negotiable.”

Similarly, Raj, a seasoned technician based in Toronto, emphasizes the value of insulated tools. “I’ve witnessed a colleague experience a mild shock due to using non-insulated pliers during a repair. It was a minor incident but a major lesson for us all. Since then, I’ve made it a point to double-check my tools before any repair task. Insulated tools are not just a recommendation; they’re a requirement in my toolkit.”

These real-life examples serve as potent reminders of the risks involved in Antminer repairs and the non-negotiable nature of safety gear and practices. By adhering to these essential precautions, technicians can safeguard themselves against the inherent dangers of electrical work, ensuring that their focus remains on the precision and efficiency of the repair, rather than the perils that accompany it.

At D-Central Technologies, we champion these safety practices, embedding them into the core of our operations. Our commitment to safety is unwavering, reflecting our dedication to providing not just expert repair services but also a safe working environment for our technicians and clients alike.

In the intricate world of Antminer repairs, the wires and connections serve as the lifelines of the device, transmitting power and data to facilitate the mining process. Given their critical role and the high voltages they often carry, handling these components with utmost care is essential for both the safety of the technician and the functionality of the Antminer. Here are some guidelines and tips for managing these vital components safely:

When working with wires and electrical connections, wearing insulated gloves is a fundamental safety practice. These gloves provide a protective barrier against accidental shocks, especially when dealing with live wires or components that might still hold a charge even after the device is powered down. The insulation helps prevent direct contact with electrical currents, significantly reducing the risk of electrocution.

A secure connection is not just vital for the efficient operation of an Antminer; it’s also crucial for safety. Loose or improperly connected wires can lead to arcing, where electricity jumps through the air from one conductor to another, creating a significant fire and shock hazard. When reconnecting wires during a repair:

Regularly inspecting the condition of wires is an essential preventive measure. Look for signs of wear and tear, such as fraying, cracking, or exposed wires, which could indicate that the insulation is compromised. Also, check for any signs of overheating, like discolored or melted insulation, which could suggest an electrical overload or a short circuit. Replacing damaged wires before they fail can prevent potential safety hazards and device malfunctions.

A common misconception is that all wires are safe to touch once the device is unplugged. However, capacitors within the Antminer can retain a charge for some time after the device is powered off, posing a risk of shock. Always approach each component with caution, assuming it could be live until proven otherwise.

Another mistake is mishandling wires, such as tugging on them to disconnect from a terminal, which can damage the wire or the connection point. Always grasp connectors or terminals, not the wires themselves, when making or breaking connections.

By adhering to these guidelines for the safe handling of wires and connections, technicians can ensure not only their safety but also the integrity and reliability of the Antminer repairs. These practices are integral to the meticulous and safety-conscious approach we champion at D-Central Technologies, ensuring that every repair is conducted with precision, care, and an unwavering commitment to safety.

A well-organized and carefully maintained workspace is not just about efficiency; it’s a critical component of safety, especially when dealing with the intricate and high-powered components of Antminers. The environment in which repairs are conducted can significantly influence the risk of accidents and the overall success of the operation. Here’s how to ensure your workspace contributes to a safe and productive repair process:

Electricity and moisture are a perilous combination. A dry workspace is essential to prevent the risk of electric shocks, short circuits, and other moisture-related hazards. Even a small spill or condensation can create a conductive path for electricity, leading to potential accidents or damage to sensitive components.

Sophie, a Bitcoin miner from Ottawa, learned the importance of a dry workspace the hard way. While performing routine maintenance on her Antminer, she accidentally knocked over a cup of coffee, causing a short circuit that not only damaged the device but also sparked a small fire. This incident underscores the critical need to keep liquids away from the workspace and to clean up any spills immediately.

A cluttered workspace can lead to confusion, mistakes, and accidents. Loose tools, scattered components, and unnecessary items not only make it difficult to find what you need but can also pose physical hazards, such as tripping or accidentally knocking over parts.

Adequate lighting is crucial in a repair workspace. It not only helps you see what you’re doing more clearly, reducing the risk of mistakes, but also helps avoid eye strain. Ensure your workspace is well-lit, preferably with adjustable lighting that can be directed where it’s most needed.

Good ventilation is essential, especially when working with soldering equipment or chemicals. Proper airflow helps dissipate fumes and heat, contributing to a safer and more comfortable working environment.

By maintaining a dry, clutter-free, and well-organized workspace, you significantly reduce the risk of accidents and enhance the efficiency and safety of Antminer repairs. These principles are integral to the operations at D-Central Technologies, where we prioritize the safety and well-being of our technicians and clients alike, ensuring that every repair is conducted in an environment that upholds the highest standards of safety and professionalism.

In the intricate realm of Antminer repairs, where the margin for error is slim, patience and precision are not just virtues; they are indispensable pillars of safety and success. The complex nature of these devices, coupled with the high stakes of maintaining operational integrity in Bitcoin mining operations, demands a meticulous approach to every repair task.

Rushing through repairs can lead to oversights that, at best, result in the need for rework, and at worst, cause further damage to the device or pose serious safety risks. Patience allows for a thorough assessment of the issue at hand, ensuring that the root cause is accurately identified and addressed. It also provides the mental space to approach each step of the repair process with the care and attention it deserves, minimizing the risk of accidental damage to delicate components or hazardous encounters with electrical circuits.

Precision in repairs goes hand in hand with patience. It involves careful attention to detail, from the disassembly and diagnosis to the repair and reassembly of the device. This precision ensures that each component is correctly handled and installed, connections are secure, and the device is restored to its optimal functionality without introducing new issues.

The use of the right tools and techniques is crucial for precision. For instance, using a torque screwdriver ensures that screws are tightened to the correct specification, preventing damage to the device. Similarly, employing magnification tools can help in accurately placing and soldering small components, reducing the risk of faulty connections that could lead to malfunctions or safety hazards.

Before reconnecting power to an Antminer post-repair, a comprehensive double-check of the work is essential. This final review acts as a safety net, catching any potential issues that might have been missed during the repair process. It involves verifying that all connections are secure, no tools or components are left inside the device, and all safety protocols have been followed.

This practice not only ensures the safety of the device and the technician but also contributes to the longevity and reliability of the Antminer, safeguarding the investment made in the valuable mining equipment.

Patience and precision in Antminer repairs are more than just best practices; they are the foundation of a safe and successful repair process. By embracing these principles, technicians can avoid common pitfalls, ensure the safety of both themselves and the device, and uphold the operational excellence of their mining operations. At D-Central Technologies, we embody these values in every repair, reflecting our commitment to quality, safety, and the success of our clients in the competitive landscape of Bitcoin mining.

While the do-it-yourself (DIY) spirit is commendable and often part of the ethos of the cryptocurrency mining community, recognizing the limits of one’s expertise and the complexity of certain repairs is crucial for maintaining both safety and the longevity of your Antminer. The intricate design and sophisticated technology of these devices mean that some issues may be beyond the scope of DIY repairs and require professional intervention.

DIY repairs can be suitable for minor issues that don’t involve the core electrical components of the Antminer or its intricate circuitry. Tasks like cleaning dust from the device, replacing a faulty fan, or resetting the software might be within the capabilities of a knowledgeable miner. However, when it comes to more complex problems—such as issues with the hash boards, power supply units, or firmware corruption—the need for specialized knowledge, tools, and experience becomes paramount.

Attempting to tackle these complex repairs without the necessary expertise can lead to further damage to the device, potentially turning a minor issue into a major, costly problem. Moreover, the risk of electrical shock or creating a fire hazard increases significantly when dealing with the high-voltage components of an Antminer without proper training and safety measures.

Professional repair services, like those offered by D-Central Technologies, bring a wealth of experience and specialized knowledge to the table. Our team of experts is equipped with the tools, diagnostic equipment, and replacement parts necessary to efficiently identify and resolve complex issues. Furthermore, professional technicians are well-versed in the safety protocols required to handle high-voltage electronics safely, ensuring that repairs are conducted without risking harm to the device or the individual.

If you’re facing an issue with your Antminer that seems beyond your repair capabilities, or if you’re unsure about the safety of a DIY repair, we encourage you to consult with the experts at D-Central Technologies. Our team is here to provide guidance, support, and professional repair services to ensure your Antminer is operating safely and efficiently. By choosing professional help for complex repairs, you’re not only safeguarding your investment in your mining equipment but also contributing to a safer, more reliable mining operation.

Remember, in the world of cryptocurrency mining, your equipment’s reliability and safety are paramount. When in doubt, seeking professional help is not just a wise choice—it’s an investment in the longevity and success of your mining endeavors.

Navigating the complexities of Antminer repairs requires more than just technical know-how; it demands a steadfast commitment to safety and precision. Throughout this guide, we’ve underscored the critical safety tips and best practices that are essential for anyone involved in the maintenance and repair of these sophisticated mining devices. From the importance of wearing protective gear and using insulated tools to the meticulous handling of wires and connections, each guideline serves as a cornerstone in the foundation of safe repair practices.

Moreover, we’ve highlighted the significance of maintaining a dry, organized workspace and the virtues of patience and precision in ensuring successful outcomes. These practices not only safeguard the technician but also protect the intricate electronics of the Antminer, ensuring its longevity and reliability in the competitive realm of Bitcoin mining.

However, it’s crucial to recognize the limits of DIY repairs and understand when it’s time to seek professional assistance. Complex issues that go beyond surface-level fixes require the expertise, tools, and experience that only professionals can provide. Attempting to address these problems without the necessary skills can lead to further damage, increased risks, and potentially significant financial loss.

At D-Central Technologies, we are committed to upholding the highest standards of safety and excellence in Antminer repairs. Our team of seasoned experts is equipped to handle a wide range of issues, from simple maintenance tasks to complex repairs, ensuring that your mining operations run smoothly and safely. We offer not just repair services but also comprehensive training and support, empowering our clients with the knowledge and skills to maintain their equipment effectively.

We invite you to prioritize safety in all your Antminer repair endeavors. Whether you’re performing routine maintenance or facing a challenging repair, remember that the well-being of both you and your equipment is paramount. For those tasks that require a professional touch, don’t hesitate to reach out to D-Central Technologies. Our expert services, training, and support are designed to meet your needs, ensuring that your mining operations are not just profitable but also safe and sustainable.

In the dynamic and ever-evolving world of cryptocurrency mining, let safety be your guiding principle and D-Central Technologies your trusted partner. Together, we can navigate the complexities of Antminer repairs, ensuring the success and security of your mining ventures.

What are Antminers?

Antminers are specialized devices known as ASICs (Application-Specific Integrated Circuits) developed by Bitmain for mining cryptocurrencies like Bitcoin. They are designed for solving complex cryptographic puzzles required in blockchain technology with unmatched efficiency and processing power.

What are common issues with Antminers?

Common issues with Antminers include overheating, dust buildup, fan failures, hash board issues, and power supply problems. These can reduce efficiency, lead to downtime or cause safety risks.

What is the significance of electrical safety in Antminer repairs?

Electrical safety is paramount in Antminer repairs due to the intricate design and high-power requirements of these devices. Adherence to safety protocols minimizes risks, ensuring both the operator’s safety and the longevity of the Antminer.

What are some pillars of electrical safety in Antminer repairs?

Pillars include preparation and protective gear, use of insulated tools, power management, knowledge and training, environmental considerations, static electricity management, and a cautious and methodical approach.

What role does D-Central Technologies play in Antminer repairs?

D-Central Technologies is Canada’s premier ASIC repair center, specializing in providing top-tier Antminer repair services with a strong emphasis on electrical safety and optimizing device performance.

Why is it sometimes necessary to seek professional help with Antminer repairs?

Professional help is necessary when repairs involve complex issues beyond the scope of DIY capabilities or concern core electrical components, requiring specialized knowledge, tools, and experience for safe and effective resolution.

How does maintaining a safe workspace contribute to Antminer repairs?

A safe workspace, which is dry, clutter-free, well-organized, and adequately lit, reduces the risk of accidents and enhances the efficiency and safety of Antminer repairs. Proper environment and tools are crucial for handling high-voltage components safely.

What are the keys to safe Antminer repairs?

Patience and precision are essential, allowing for thorough assessment, careful handling, and accurate reassembly of the device. These practices prevent oversights and minimize the risk of accidents or further damage to the Antminer.

DISCLAIMER: D-Central Technologies and its associated content, including this blog, do not serve as financial advisors or official investment advisors. The insights and opinions shared here or by any guests featured in our content are provided purely for informational and educational purposes. Such communications should not be interpreted as financial, investment, legal, tax, or any form of specific advice. We are committed to advancing the knowledge and understanding of Bitcoin and its potential impact on society. However, we urge our community to proceed with caution and informed judgment in all related endeavors.

Related Posts

The aquaculture industry is facing an ongoing challenge of maintaining the optimal temperature for aquatic organisms, which can be a

Discover how D-Central’s innovative solutions are transforming residential Bitcoin mining, making it more accessible, efficient, and profitable for homeowners. Learn

In today’s rapidly evolving technological landscape, Nvidia stands as a titan in the AI and data center industry. Known for