Why Are You Paying to Freeze? Turn Your S19 into a Heater!

As winter approaches and heating bills rise, homeowners are always on the lookout for ways to stay warm without breaking

4479 Desserte Nord Autoroute 440, Laval, QC H7P 6E2

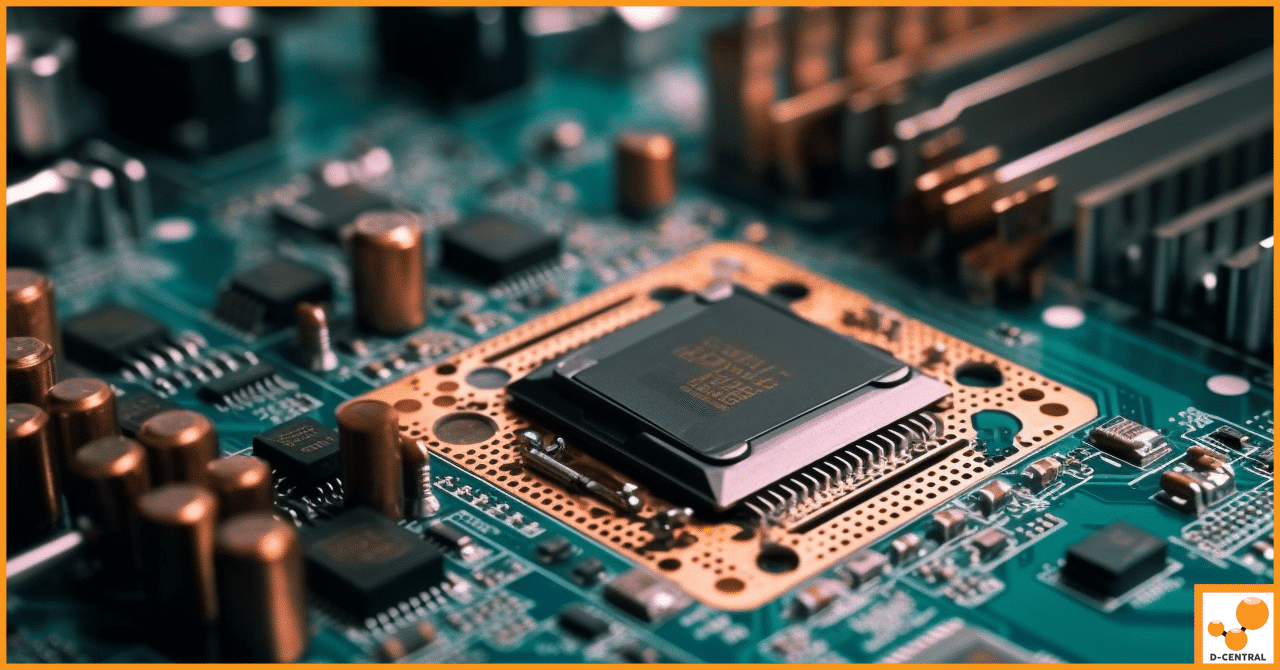

In the rapidly evolving landscape of cryptocurrency mining, Application-Specific Integrated Circuit (ASIC) miners have emerged as the gold standard for efficiency and performance. Unlike their predecessors, which included GPUs and CPUs, ASIC miners are designed with a singular focus: to mine cryptocurrency at unparalleled speeds while minimizing power consumption. This specialization has catapulted ASIC mining to the forefront of the cryptocurrency world, enabling miners to achieve greater profitability and efficiency in their operations.

However, the intense computational power of ASIC miners comes with its own set of challenges, chief among them being the management of heat. The compact, high-performance nature of ASIC chips means they generate a significant amount of heat during operation. If not properly managed, this heat can lead to throttling, reduced efficiency, and even premature hardware failure, significantly impacting the miner’s longevity and profitability. This is where thermal management becomes a cornerstone of successful ASIC mining operations.

Central to effective thermal management is the use of thermal paste, a thermally conductive compound that plays a pivotal role in maintaining optimal ASIC miner performance. Thermal paste is applied between the ASIC chip and its cooler, filling microscopic air gaps in the interface to enhance heat transfer from the chip to the cooler. By improving thermal conductivity, thermal paste ensures that heat is efficiently dissipated, keeping the ASIC chip within safe operating temperatures. This not only prevents overheating and potential damage but also maintains the miner’s performance at peak levels.

The choice of thermal paste and the precision in its application can make a significant difference in the performance and longevity of ASIC miners. With the right thermal paste, miners can maximize their hardware’s efficiency, extend its lifespan, and, by extension, secure their investment in the competitive realm of cryptocurrency mining. As such, understanding the nuances of thermal paste selection and application has become essential knowledge for anyone involved in ASIC mining.

Thermal paste, also known by several aliases including thermal compound, thermal grease, or heat sink compound, is a thermally conductive (but typically electrically insulating) substance. Its primary role is to improve the thermal efficiency of heat transfer components in electronic devices and computers, and it is especially crucial in the high-stakes world of ASIC mining.

Thermal paste is a substance designed to fill the microscopic imperfections found on the surfaces of heat sinks and the components they cool. These imperfections, though invisible to the naked eye, can trap air—a poor conductor of heat—thereby reducing the efficiency of heat transfer. By filling these gaps, thermal paste eliminates air pockets and ensures a direct path for heat to move from the ASIC chip to its cooler, significantly enhancing the cooling process.

The mechanism of thermal paste is straightforward yet highly effective. When applied between the ASIC chip and its cooling solution (such as a heat sink or liquid cooling block), thermal paste forms a continuous, conductive bridge that facilitates the efficient transfer of heat away from the chip. This process is critical for maintaining the optimal performance of ASIC miners, as excessive heat can lead to throttling, where the device automatically reduces its performance to prevent overheating, or even permanent damage to the chip.

The effectiveness of thermal paste comes from its thermal conductivity, a measure of a material’s ability to conduct heat. High thermal conductivity means that the paste can quickly transfer heat from the ASIC chip to the cooler, keeping the chip at a safe operating temperature even under intense mining operations.

In the context of ASIC mining, thermal conductivity is a key performance metric. The higher the thermal conductivity of a paste, the more efficiently it can transfer heat. This efficiency directly impacts the ASIC miner’s ability to operate continuously at high speeds without overheating, ensuring stable and reliable mining performance over time.

Moreover, effective thermal management through high-quality thermal paste can significantly extend the lifespan of ASIC miners. By keeping temperatures within safe limits, the wear and tear on the hardware are minimized, protecting the miner’s investment and maximizing its profitability in the long run.

In summary, thermal paste plays an indispensable role in ASIC mining by ensuring efficient heat transfer, maintaining performance, and prolonging hardware longevity. Its application is a critical step in setting up any mining operation, underscoring the importance of selecting a high-quality product and applying it correctly to achieve the best thermal management possible.

In the precision-engineered world of ASIC mining, where every hash and watt counts towards profitability, the role of thermal paste transcends its humble appearance. The choice of thermal paste can significantly influence both the performance and durability of ASIC miners, making it a critical consideration for any serious miner.

High-quality thermal paste ensures optimal heat conduction between the ASIC chip and its cooling system, a key factor in maintaining the chip’s performance under continuous operation. Good thermal paste has a high thermal conductivity, allowing for efficient heat transfer and helping to keep the ASIC chip at lower temperatures. This not only boosts the immediate hashing performance by preventing thermal throttling but also contributes to the long-term durability of the miner. Consistently lower operating temperatures reduce the thermal stress on components, thereby extending their operational lifespan and maintaining performance levels over time.

The repercussions of inadequate thermal management in ASIC mining operations can be severe, directly impacting the miner’s profitability and operational lifespan.

These examples underscore the tangible benefits of investing in quality thermal paste for ASIC miners. Not only does it enhance immediate mining performance by ensuring efficient heat transfer, but it also plays a crucial role in safeguarding the miner’s hardware investment over the long term. In the competitive and margin-focused world of cryptocurrency mining, the right thermal paste can make all the difference.

Selecting the right thermal paste is a critical decision for ASIC miners, impacting not just the efficiency of heat transfer but also the overall performance and longevity of the mining hardware. Here are key factors to consider when evaluating thermal paste options:

Evaluating thermal paste for ASIC miners involves considering these key factors to ensure that you select a product that meets the specific needs of your mining operation. By doing so, you can enhance the efficiency, performance, and longevity of your ASIC mining hardware.

The right thermal paste can significantly enhance the performance and longevity of ASIC miners. Here are some of the top recommended thermal pastes, each with unique properties catering to different mining needs:

Selecting the right thermal paste involves considering the specific requirements of your ASIC mining setup, including the environmental conditions, the intensity of mining operations, and budget constraints. Each of these recommended thermal pastes brings something unique to the table, ensuring that there’s a solution for every type of miner out there.

Proper application of thermal paste is crucial for the efficient operation of ASIC miners. Here’s a comprehensive guide to applying thermal paste, ensuring optimal heat dissipation and miner performance.

The amount of thermal paste used can significantly affect thermal performance. Too little paste may not cover the entire chip, leading to hot spots, while too much can act as an insulator, trapping heat.

Proper application and regular maintenance of thermal paste are key to maximizing the efficiency and lifespan of your ASIC miners. By following these best practices and techniques, you can ensure your mining operation runs smoothly and effectively.

Effective cooling is paramount for ASIC miners to operate efficiently and maintain their longevity. Thermal paste plays a crucial role within this cooling ecosystem, but it’s just one component of a comprehensive cooling strategy. Understanding how to maintain the entire cooling system can significantly enhance your miner’s performance and durability.

Thermal paste acts as a critical intermediary between the ASIC chip and its heat dissipation components, such as heat sinks or liquid cooling blocks. By filling microscopic gaps and removing air pockets, it ensures optimal heat transfer away from the chip. However, the effectiveness of thermal paste is complemented by the overall efficiency of the cooling system, which may include fans, heat sinks, liquid cooling solutions, and the miner’s casing design. Together, these components work to maintain an optimal operating temperature, preventing thermal throttling and prolonging the miner’s life.

To ensure your ASIC miner’s cooling system remains effective, adhere to a regular maintenance schedule:

Maintaining your ASIC miner’s cooling system is an ongoing process that requires regular attention and care. By implementing additional cooling solutions, practicing good maintenance habits, and adhering to a regular schedule, you can significantly improve your miner’s performance and lifespan. Remember, a well-cooled miner is a happy miner, leading to more efficient and profitable mining operations.

The exploration of thermal management complexities for ASIC miners reveals an essential truth: choosing the right thermal paste is far from a trivial concern—it’s a fundamental aspect of running efficient and sustainable mining operations. High-quality thermal paste emerges as a critical ally in the fight against overheating, ensuring that ASIC miners operate at peak performance amidst the intense demands of cryptocurrency mining.

Thermal paste serves as an essential bridge for heat transfer, effectively connecting the ASIC chip to its cooling mechanisms. This vital component plays a key role in preserving the health and efficiency of mining hardware, safeguarding against overheating, thermal throttling, and premature equipment failure. Consequently, selecting the appropriate thermal paste is a crucial decision that influences not just the immediate functionality of your miners but also their long-term viability and, ultimately, the profitability of your mining activities.

However, effective thermal management goes beyond merely applying top-notch thermal paste. It involves a comprehensive approach to cooling that includes improved airflow, consistent maintenance of cooling components, and the implementation of environmental controls. We’ve underscored the importance of adhering to regular maintenance schedules and integrating additional cooling strategies to significantly enhance the performance and lifespan of your ASIC miners. Therefore, prioritizing superior thermal management is essential within your overall strategy for mining operation maintenance.

The ASIC mining landscape is continuously evolving, with advancements in technologies and maintenance methodologies emerging regularly. We encourage you to further explore this field, broadening your understanding and keeping up with the latest in ASIC mining technologies and maintenance insights. Doing so will help ensure that your mining operations stay competitive, efficient, and profitable in the ever-changing world of cryptocurrency mining.

At D-Central, we understand the critical importance of thermal management in ASIC mining operations. That’s why we offer specialized repasting services for ASIC miners, designed to enhance your hardware’s performance and extend its lifespan. Our expert team uses only the highest quality thermal paste and employs best practices in thermal management to ensure your mining venture is as productive and enduring as possible.

In conclusion, the careful selection and application of thermal paste, combined with thorough thermal management practices, are crucial for the success of your ASIC mining operations. By choosing D-Central’s repasting services and embracing comprehensive thermal management, you not only protect your hardware but also maximize its efficiency, paving the way for a successful and long-lasting venture into cryptocurrency mining.

What is an ASIC Miner?

An Application-Specific Integrated Circuit (ASIC) miner is a device that is designed specifically for mining cryptocurrency with unparalleled efficiency and speed while minimizing power consumption.

Why is thermal paste important for ASIC miners?

Thermal paste is crucial for ASIC miners as it improves thermal conductivity between the ASIC chip and its cooler. It ensures efficient heat dissipation, prevents overheating, and maintains peak performance, which is vital for the longevity and profitability of mining operations.

How does thermal paste work?

Thermal paste fills microscopic gaps between the ASIC chip and the cooler, eliminating air pockets that impede heat transfer. This enhances the cooler’s ability to dissipate heat away from the chip, maintaining optimal operating temperatures and performance.

What factors should be considered when selecting thermal paste for ASIC miners?

When selecting thermal paste, consider thermal conductivity, electrical conductivity, composition (metal-based, ceramic, or silicon-based), viscosity, ease of application, and price-performance balance. It’s crucial to choose a paste that meets the specific needs of your mining operation.

How often should thermal paste be replaced on ASIC miners?

Thermal paste should be replaced every 1-2 years, depending on the miner’s operating conditions and the quality of the paste used. Regular maintenance and monitoring of temperatures can indicate when a replacement is necessary.

What are some recommended thermal pastes for ASIC miners?

Top recommended thermal pastes include Arctic MX-6, Noctua NT-H2, Thermal Grizzly Kryonaut, Prolimatech PK-3 Nano Aluminum, Alphacool Apex, Thermalright TF8, Grizzly Kryonaut Extreme, D-Central’s Hashboard Thermal Paste, and IC Diamond. Each paste has unique properties suited for different mining needs.

What are the best practices for applying thermal paste to ASIC miners?

Best practices include cleaning the chip and cooler surfaces, applying a small amount of paste (using the pea or line method), and spreading it evenly if necessary. It’s vital to avoid overapplication and ensure even coverage for optimal heat transfer.

Why is maintaining the cooling system important for ASIC miners?

Maintaining the cooling system is crucial as it enhances the performance and lifespan of ASIC miners. Effective cooling prevents overheating, thermal throttling, and premature equipment failure, ensuring efficient and profitable mining operations.

What additional cooling solutions can be implemented for ASIC miners?

Additional cooling solutions include enhancing airflow, regular cleaning of heat sinks, investing in liquid cooling systems, controlling the environmental temperature, and utilizing monitoring tools to detect overheating issues promptly.

DISCLAIMER: D-Central Technologies and its associated content, including this blog, do not serve as financial advisors or official investment advisors. The insights and opinions shared here or by any guests featured in our content are provided purely for informational and educational purposes. Such communications should not be interpreted as financial, investment, legal, tax, or any form of specific advice. We are committed to advancing the knowledge and understanding of Bitcoin and its potential impact on society. However, we urge our community to proceed with caution and informed judgment in all related endeavors.

Related Posts

As winter approaches and heating bills rise, homeowners are always on the lookout for ways to stay warm without breaking

In the ever-evolving world of finance, digital currencies have emerged as a groundbreaking development, reshaping how we think about money

As an avid cryptocurrency miner, I understand the importance of maintaining my mining equipment to ensure optimal performance and a