Mastering the Art of ASIC Repair

Are you interested in repairing ASIC machines such as L3s, S9s, S17s and S19s? If so, receiving proper training from

4479 Desserte Nord Autoroute 440, Laval, QC H7P 6E2

In the rapidly evolving world of cryptocurrency mining, efficiency and innovation are paramount. As miners seek to maximize their returns in a competitive landscape, the focus on advanced technologies and methodologies has never been more critical. Among these, the cooling of mining hardware stands out as a fundamental aspect that directly impacts operational efficiency, hardware longevity, and overall profitability.

Cryptocurrency mining, at its core, involves the use of specialized hardware known as Application-Specific Integrated Circuits (ASICs) to solve complex cryptographic puzzles. This process, essential for transaction verification and blockchain security, is inherently energy-intensive and generates significant amounts of heat. Efficiently managing this heat is crucial; excessive temperatures can lead to reduced performance, increased failure rates, and ultimately, diminished returns on investment.

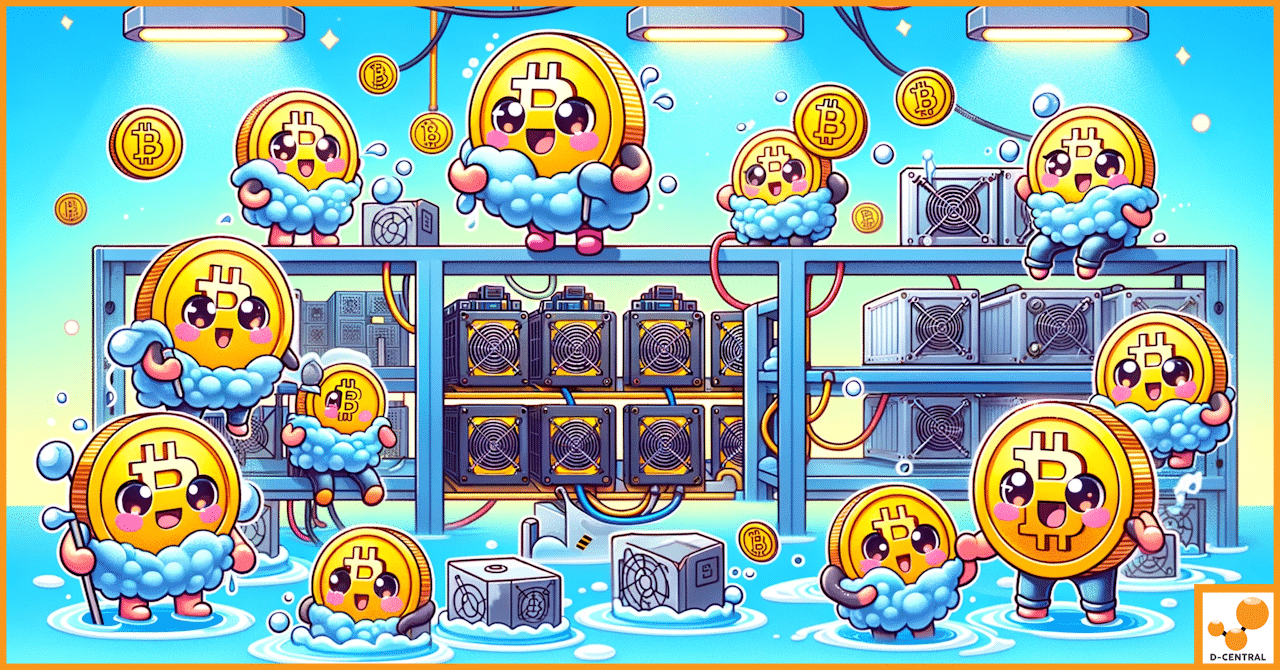

Enter ASIC immersion cooling, a cutting-edge solution that has been gaining traction among mining enthusiasts and professionals alike. This innovative cooling method involves submerging ASIC miners in a thermally conductive, but electrically insulating liquid. Unlike traditional air or liquid cooling systems, immersion cooling offers direct and uniform heat dissipation from the mining hardware, ensuring optimal operating temperatures even under the most intense workloads.

The adoption of immersion cooling in cryptocurrency mining is not merely a trend but a transformative shift towards enhancing mining operations’ efficiency, performance, and sustainability. This article aims to explore the multifaceted benefits of ASIC immersion cooling, delving into how this technology is reshaping the landscape of cryptocurrency mining by offering a solution that aligns with the industry’s growing demands for higher efficiency, improved hardware performance, and a commitment to environmental sustainability.

ASIC miners are the backbone of cryptocurrency mining, designed specifically to perform the computations required for mining digital currencies like Bitcoin. Unlike general-purpose hardware such as CPUs or GPUs, ASICs are tailored for a single process, making them incredibly efficient at executing the hashing algorithms central to blockchain technology. This specialization allows ASIC miners to offer unparalleled performance in terms of hash rate, a critical metric in mining that represents the number of attempts to solve a block per second.

The role of ASIC miners in cryptocurrency mining is pivotal. They contribute to the security and functionality of blockchain networks by validating transactions and creating new blocks. In return for their computational efforts, miners are rewarded with newly minted coins and transaction fees, making mining a potentially lucrative endeavor. However, the profitability of mining is heavily influenced by the efficiency and effectiveness of the mining hardware, particularly its ability to manage heat.

The intense computational work performed by ASIC miners generates a significant amount of heat. Effective heat management is crucial, as high temperatures can lead to thermal throttling, where the miner’s performance is automatically reduced to prevent overheating. Prolonged exposure to excessive heat can also accelerate hardware degradation, leading to frequent breakdowns and a shorter operational lifespan.

Traditional cooling methods, such as air cooling and liquid cooling, have been the standard solutions to this challenge. Air cooling, the most common approach, uses fans to circulate air around the ASIC miners, dissipating heat into the surrounding environment. While relatively simple and cost-effective, air cooling struggles with efficiency, especially in densely packed mining setups or in regions with high ambient temperatures. The reliance on air movement also introduces issues like dust accumulation, which can further impede cooling performance and necessitate regular maintenance.

Liquid cooling, on the other hand, involves circulating a coolant liquid around the components of the ASIC miner, absorbing and transferring the heat to a radiator where it is expelled. While more efficient than air cooling, traditional liquid cooling systems are complex, requiring pumps, tubing, and radiators. This complexity not only increases the risk of leaks and component failure but also limits the scalability of mining operations due to the intricate setup and space requirements.

Both traditional cooling methods, while effective to varying degrees, present limitations in their ability to manage the substantial heat generated by ASIC miners efficiently. These challenges underscore the need for more advanced cooling solutions that can enhance the performance, reliability, and scalability of cryptocurrency mining operations.

Immersion cooling represents a paradigm shift in the approach to managing the substantial heat produced by ASIC miners. This innovative technology not only addresses the limitations of traditional cooling methods but also sets a new standard for efficiency, reliability, and scalability in cryptocurrency mining operations.

Immersion cooling involves submerging electronic components, such as ASIC miners, directly into a dielectric liquid that is both thermally conductive and electrically insulating. This liquid rapidly absorbs the heat generated by the miners, efficiently dissipating it away from the hardware. Unlike air and traditional liquid cooling, which rely on intermediary materials (like heatsinks) to transfer heat, immersion cooling allows for direct contact between the coolant and the components, facilitating immediate and uniform heat removal.

The process begins with the placement of ASIC miners into a specially designed tank filled with the cooling liquid. As the miners operate and generate heat, the liquid absorbs this heat, effectively maintaining the miners at optimal operating temperatures. The heated liquid is then circulated out of the tank to a heat exchanger, where the heat is expelled, and the cooled liquid is recirculated back into the tank, creating a continuous and efficient cooling cycle.

Immersion cooling can be implemented in two distinct forms: single-phase and two-phase systems, each with its unique mechanism for heat dissipation.

An immersion cooling system comprises several key components, each playing a crucial role in its operation:

Together, these components form a highly efficient and effective cooling solution, capable of maintaining optimal operating conditions for ASIC miners, even under the most demanding workloads. Immersion cooling not only enhances the performance and longevity of mining hardware but also opens new possibilities for the design and scalability of cryptocurrency mining operations.

Immersion cooling offers a suite of advantages that address many of the challenges faced by traditional cooling methods in cryptocurrency mining. These benefits not only enhance the operational efficiency of mining rigs but also contribute to their longevity and overall performance.

As the cryptocurrency mining industry grows, so does its environmental footprint, prompting a critical examination of the sustainability of mining practices. Immersion cooling, with its advanced efficiency and performance benefits, also brings to the table significant environmental considerations that align with the growing demand for greener mining solutions.

Immersion cooling systems, by virtue of their high efficiency, have a lower environmental impact compared to traditional air and liquid cooling methods. The direct heat transfer mechanism in immersion cooling reduces the need for energy-intensive cooling components like fans and air conditioning units, leading to a substantial decrease in energy consumption. This reduction in energy use directly translates to lower greenhouse gas emissions, assuming the energy source is not entirely renewable. Moreover, the ability to densely pack mining hardware in immersion cooling setups can lead to more efficient use of space and resources, further minimizing the ecological footprint of mining operations.

The choice of coolant plays a significant role in the environmental sustainability of immersion cooling systems. Traditional coolants, while effective, can sometimes contain chemicals that are harmful to the environment. In response, there has been a shift towards using non-conductive, eco-friendly coolants that offer the necessary thermal conductivity without the adverse environmental impact. These coolants are often biodegradable, non-toxic, and have a low global warming potential (GWP), making them a more sustainable choice for immersion cooling. Companies specializing in immersion cooling solutions are increasingly focusing on developing and promoting these eco-friendly coolants as part of their commitment to sustainable mining practices.

One of the most promising aspects of immersion cooling from an environmental standpoint is the potential for waste heat recovery and utilization. The heat absorbed by the cooling liquid can be repurposed for secondary uses, such as heating buildings, greenhouses, or even in industrial processes, thereby turning a byproduct of mining into a valuable resource. This not only improves the overall energy efficiency of the mining operation but also contributes to a circular economy model where waste from one process is used as input for another.

For example, a mining operation located in a colder climate could use the excess heat from its immersion cooling system to warm its facilities, reducing the need for additional heating sources and thereby lowering its overall energy consumption. Similarly, the integration of waste heat recovery systems in mining operations located near agricultural or industrial facilities could provide a sustainable source of heat, further reducing the environmental impact of both the mining and the partnered operations.

While immersion cooling offers numerous benefits for cryptocurrency mining operations, it’s important to acknowledge and address the challenges and considerations that come with implementing this technology. Understanding these factors is crucial for miners contemplating the transition to immersion cooling.

One of the primary hurdles in adopting immersion cooling is the initial setup cost. The investment required for immersion cooling systems can be significantly higher than traditional air or liquid cooling setups. This includes the cost of the immersion tanks, cooling liquid, heat exchange systems, and any modifications needed to accommodate the new cooling infrastructure. For mining operations considering immersion cooling, a thorough investment analysis is essential to weigh the upfront costs against the long-term benefits, such as improved efficiency, reduced energy consumption, and extended hardware lifespan. It’s also important to consider potential savings from reduced maintenance costs and the possibility of lower operational expenses over time.

While immersion cooling systems generally require less maintenance than traditional cooling methods, they are not entirely maintenance-free. Regular checks and maintenance are necessary to ensure the system operates efficiently. This includes monitoring the quality and level of the cooling liquid, inspecting pumps and heat exchangers for optimal performance, and ensuring that the filtration system effectively removes any particulates or contaminants from the liquid. Additionally, miners need to be prepared for the operational considerations unique to immersion cooling, such as managing the cooling liquid’s lifecycle and understanding the process for safely adding or removing hardware from the immersion tanks.

Safety is a paramount concern when dealing with immersion cooling systems, given the use of large volumes of liquid in close proximity to electrical equipment. Ensuring the cooling liquid is non-conductive and compatible with the hardware is crucial to prevent any risk of electrical shorts or damage. Furthermore, the system should be designed to contain any leaks and prevent liquid spillage, protecting both the mining hardware and the surrounding environment.

Best practices for immersion cooling include:

By carefully considering these challenges and adhering to best practices, miners can effectively mitigate the risks associated with immersion cooling and fully leverage its benefits for their operations.

The journey through the intricacies of ASIC immersion cooling reveals a technology poised to redefine the landscape of cryptocurrency mining. With its unparalleled efficiency in heat dissipation, immersion cooling stands as a beacon of innovation, addressing the perennial challenges of overheating, energy consumption, and noise pollution that have long plagued mining operations. The key benefits of immersion cooling—enhanced cooling efficiency, reduced energy consumption, space optimization, noise reduction, and improved hardware lifespan—collectively contribute to a more sustainable, profitable, and environmentally friendly mining practice.

The transformative potential of immersion cooling extends beyond mere operational improvements; it embodies a shift towards more responsible mining practices, aligning with the broader goals of sustainability and environmental stewardship. By adopting immersion cooling, miners can significantly reduce their carbon footprint, contribute to energy conservation, and pave the way for a greener future in the digital currency realm.

As the cryptocurrency mining industry continues to evolve, the adoption of advanced cooling solutions like immersion cooling will be crucial in navigating the challenges of scalability, efficiency, and sustainability. For those ready to embark on this transformative journey, D-Central Technologies stands at the forefront, ready to guide and support.

Embrace the future of cryptocurrency mining with D-Central Technologies. Explore our cutting-edge immersion cooling solutions tailored to meet your mining needs, from small-scale setups to industrial-scale operations. Join us in our commitment to innovation, efficiency, and sustainability. Visit our website, reach out to our experts, and discover how we can elevate your mining operation to new heights. Together, let’s redefine what’s possible in cryptocurrency mining.

DISCLAIMER: D-Central Technologies and its associated content, including this blog, do not serve as financial advisors or official investment advisors. The insights and opinions shared here or by any guests featured in our content are provided purely for informational and educational purposes. Such communications should not be interpreted as financial, investment, legal, tax, or any form of specific advice. We are committed to advancing the knowledge and understanding of Bitcoin and its potential impact on society. However, we urge our community to proceed with caution and informed judgment in all related endeavors.

Related Posts

Are you interested in repairing ASIC machines such as L3s, S9s, S17s and S19s? If so, receiving proper training from

In the dynamic world of cryptocurrencies, Bitcoin stands as a towering figure, a digital gold rush drawing in a diverse

In the rapidly evolving world of cryptocurrency, ASIC (Application-Specific Integrated Circuit) mining has emerged as a cornerstone of the blockchain