In the dynamic world of cryptocurrency mining, Application-Specific Integrated Circuit (ASIC) miners have emerged as pivotal tools in the quest for digital currency. Unlike their predecessors, ASIC miners are designed with a singular purpose: to mine cryptocurrencies like Bitcoin with unparalleled efficiency and speed. This specialized hardware has revolutionized the mining landscape, offering miners the ability to generate higher profits by significantly increasing hash rates while minimizing energy consumption. The importance of ASIC miners in cryptocurrency mining cannot be overstated; they are the backbone of mining operations, driving the industry forward in a highly competitive market.

As the cryptocurrency mining industry evolves, so too does the approach to mining operations. Remote mining operations have become increasingly popular, allowing miners to manage and operate their ASIC hardware from distant locations. This modern mining model leverages advanced technologies to monitor and control mining activities, enabling miners to tap into geographically diverse regions where energy costs are lower or where environmental conditions are more favorable for mining. Remote operations not only optimize the cost-effectiveness of mining endeavors but also introduce flexibility and scalability into the mining process, attributes that are essential in the fast-paced cryptocurrency domain.

However, managing ASIC maintenance in remote mining operations presents a unique set of challenges. The logistical hurdles of accessing remote sites, the intricacies of monitoring hardware health from afar, and the critical need for effective cooling solutions in varied climates are just a few of the obstacles that miners must navigate. Moreover, network reliability and security risks add layers of complexity to remote operations, demanding innovative solutions and best practices to ensure uninterrupted and secure mining activities.

This article delves into the challenges associated with ASIC maintenance in remote mining operations and explores comprehensive solutions to overcome these obstacles. From leveraging advanced monitoring technologies to implementing effective cooling systems and enhancing network security, we will uncover the strategies that enable miners to maintain optimal performance of their ASIC hardware, regardless of the geographical boundaries. Join us as we navigate the intricacies of remote ASIC maintenance, highlighting the importance of innovation and adaptability in sustaining the profitability and efficiency of cryptocurrency mining operations.

Understanding ASIC Maintenance in Remote Mining Operations

Maintaining optimal performance and efficiency in cryptocurrency mining operations is crucial for maximizing profitability and ensuring the longevity of the mining hardware. Within this context, the maintenance of Application-Specific Integrated Circuit (ASIC) miners holds paramount importance, especially as the industry gravitates towards remote mining operations. This section explores the critical role of ASIC maintenance and the unique challenges presented by remote operations.

The Importance of ASIC Maintenance

ASIC miners are the workhorses of the cryptocurrency mining world, designed to perform the singular task of mining digital currencies with exceptional efficiency. However, like any high-performance computing hardware, they are subject to wear and tear, especially under continuous operation. Regular maintenance of these devices is not just a recommendation; it’s a necessity.

Why Regular Maintenance is Crucial:

- Optimal Performance: Regular maintenance ensures that ASIC miners operate at their peak efficiency. Dust buildup, for instance, can impede airflow and lead to overheating, which in turn can reduce the miner’s hash rate and efficiency. By keeping the hardware clean and well-maintained, miners can avoid such pitfalls.

- Prevention of Downtime: Unscheduled downtimes can be costly in the mining business, where every minute counts. Through routine maintenance, potential issues can be identified and rectified before they lead to significant downtime, ensuring a steady stream of mining activity.

- Longevity of Hardware: Continuous operation in less-than-ideal conditions can accelerate the wear and tear on ASIC miners. Regular maintenance extends the lifespan of the hardware, protecting the investment made by the mining operation.

Impact of Maintenance on Efficiency, Longevity, and Profitability:

Efficient and well-maintained ASIC miners directly contribute to the profitability of mining operations. By maximizing the operational efficiency and extending the usable life of the hardware, miners can ensure a higher return on investment. Furthermore, the avoidance of prolonged downtimes means that mining operations can continue to generate revenue without interruption, enhancing overall profitability.

Unique Challenges of Remote Operations

While remote mining operations offer numerous advantages, including access to cheaper electricity and cooler climates, they also introduce a set of unique challenges that can complicate ASIC maintenance.

Logistical, Technical, and Operational Challenges:

- Accessibility: Remote mining sites, often located in geographically isolated areas, can make it difficult to perform regular maintenance. The logistical challenge of transporting technicians and equipment to these sites can lead to delays in maintenance schedules.

- Remote Monitoring and Diagnostics: Ensuring the health and performance of ASIC miners from a distance requires sophisticated remote monitoring systems. These systems must be capable of providing real-time data on the miners’ operational status, which necessitates a reliable and secure network infrastructure.

- Technical Expertise: The technical expertise required to maintain and troubleshoot ASIC miners may not always be readily available in remote locations, necessitating remote support or the transportation of specialists to the site.

The Role of Environmental Factors:

Environmental factors play a significant role in exacerbating maintenance needs for remote mining operations. Extreme temperatures, humidity, and dust can all impact the performance and longevity of ASIC miners. For instance, mining operations in hot climates may struggle with overheating issues, while those in humid environments may face challenges with moisture and corrosion. Addressing these environmental challenges requires tailored cooling and maintenance solutions to ensure the stable operation of ASIC miners under varying conditions.

In summary, while remote mining operations present an attractive proposition for cryptocurrency mining, they also demand a comprehensive approach to ASIC maintenance. Understanding and addressing the unique challenges of remote operations are essential for maintaining the efficiency, longevity, and profitability of ASIC miners in the competitive landscape of cryptocurrency mining.

Key Challenges in ASIC Maintenance for Remote Mining Operations

The shift towards remote mining operations has introduced a new paradigm in the maintenance of ASIC miners, bringing to the forefront a set of challenges that are distinct from traditional, on-site mining setups. These challenges not only complicate the maintenance process but also pose risks to the efficiency and security of mining operations. This section delves into the primary obstacles encountered in the maintenance of ASIC miners in remote locations.

Accessibility and Logistic Hurdles

One of the most significant challenges in maintaining ASIC miners at remote sites is the sheer difficulty of accessing these locations. Remote mining operations are often situated in areas chosen for their low energy costs and favorable environmental conditions, which can be far removed from major urban centers or in geographically isolated regions. This remoteness poses a considerable challenge for the routine maintenance and repair of ASIC miners.

Difficulties in Accessing Remote Mining Sites for Maintenance:

- The physical distance and potentially challenging terrain can delay the arrival of maintenance teams and the necessary equipment, leading to prolonged downtimes.

- In some cases, the sites may be accessible only by specialized modes of transportation, further complicating logistics and increasing maintenance costs.

Complexity of Transporting Parts and Personnel:

- Transporting heavy and sensitive ASIC mining equipment, along with replacement parts, requires careful planning and secure packaging to prevent damage during transit.

- Coordinating the movement of technical personnel, who are essential for performing complex repairs and maintenance, adds another layer of logistical complexity, especially when dealing with international travel and local regulations.

Monitoring and Diagnostics from Afar

Effective maintenance of ASIC miners relies heavily on the ability to monitor their health and performance accurately. Remote operations necessitate advanced systems for real-time monitoring and diagnostics, which come with their own set of challenges.

Challenges in Remotely Monitoring ASIC Health and Performance:

- Ensuring continuous and reliable data transmission from ASIC miners to remote monitoring centers can be challenging, especially in areas with limited or unreliable internet connectivity.

- The granularity of data required for effective diagnostics may exceed the capabilities of some remote monitoring systems, leading to gaps in the information available to maintenance teams.

Limitations of Existing Remote Diagnostic Tools:

- Many remote diagnostic tools may not provide the depth of analysis needed to identify subtle issues before they escalate into major problems, limiting preventive maintenance efforts.

- The integration of diagnostic tools with existing mining management software can be complex, requiring custom solutions that increase the cost and complexity of maintenance operations.

Overheating and Environmental Concerns

ASIC miners generate a significant amount of heat during operation, making effective cooling a critical concern, especially in remote locations where environmental conditions can exacerbate overheating issues.

The Critical Issue of Managing Heat in Remote Operations:

- Remote sites selected for their low ambient temperatures can experience seasonal variations that impact cooling efficiency, requiring adaptive cooling solutions.

- The cost and complexity of implementing and maintaining advanced cooling systems in remote locations can be significant, impacting the overall profitability of mining operations.

Environmental Challenges Unique to Remote Locations:

- Dust, humidity, and other environmental factors can affect the performance and longevity of ASIC miners, necessitating regular cleaning and maintenance that may be difficult to perform remotely.

- Extreme weather events, common in some remote areas, can pose risks to both the ASIC miners and the infrastructure supporting them, such as power supplies and internet connectivity.

Network Reliability and Security Risks

The reliance on network connectivity for remote monitoring and control of ASIC miners introduces challenges related to network reliability and security.

The Impact of Network Unreliability on Remote Monitoring:

- Intermittent or slow internet connections can hinder real-time monitoring efforts, delaying the detection of issues and the initiation of corrective actions.

- Network outages, whether due to technical failures or environmental factors, can leave remote mining operations blind, unable to monitor or control ASIC miners.

Security Vulnerabilities in Remote Operation Setups:

- Remote access to mining operations opens up potential vulnerabilities to cyberattacks, including the risk of unauthorized access to control systems and sensitive data.

- Ensuring the security of remote monitoring and control systems requires continuous vigilance and updates to protect against evolving cyber threats.

Addressing these challenges is crucial for the success and sustainability of remote ASIC mining operations. The following sections will explore solutions and best practices to overcome these obstacles, ensuring efficient, secure, and profitable mining activities.

Solutions and Best Practices for Remote ASIC Maintenance

The challenges of maintaining ASIC miners in remote mining operations are significant, but not insurmountable. By leveraging advanced technologies and implementing strategic solutions, mining operations can overcome these obstacles to ensure efficient, secure, and profitable operations. This section explores the solutions and best practices that are shaping the future of remote ASIC maintenance.

Leveraging Advanced Monitoring Technologies

In the era of digital transformation, smart technologies and the Internet of Things (IoT) have become pivotal in revolutionizing remote monitoring capabilities. These technologies offer a new paradigm for maintaining ASIC miners in remote locations, providing real-time data and insights that are critical for proactive maintenance and operational efficiency.

Introduction to Smart Technologies and IoT for Remote Monitoring:

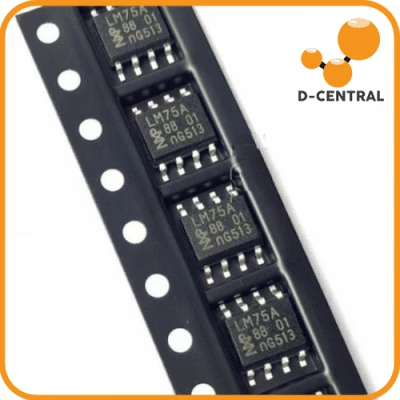

- Smart sensors and IoT devices can be integrated into ASIC miners to monitor a wide range of operational parameters, including temperature, power consumption, and hash rate, in real-time.

- These technologies enable predictive maintenance by identifying patterns and anomalies that may indicate potential failures, allowing for preemptive action to avoid downtime.

Benefits of Blockchain and Smart Contracts for Secure Operations:

- Blockchain technology can be utilized to create a secure, immutable record of all maintenance activities and operational data, enhancing transparency and accountability.

- Smart contracts can automate certain maintenance processes and payments, ensuring that service level agreements are met and reducing the administrative burden on mining operations.

Implementing Effective Cooling Solutions

Effective cooling is critical for preventing overheating and ensuring the longevity of ASIC miners, especially in remote operations where environmental conditions can vary widely. Innovative cooling technologies and custom solutions can address these challenges, maintaining optimal operating temperatures regardless of location.

Overview of Innovative Cooling Technologies for ASIC Miners:

- Immersion cooling systems, where ASIC miners are submerged in a non-conductive liquid, offer superior cooling efficiency by directly absorbing heat from the components.

- Advanced air cooling solutions, including high-flow fans and heat exchangers, can be optimized for remote environments to provide effective heat dissipation.

Custom Solutions for Challenging Environments:

- Tailored cooling solutions can be designed to address the specific environmental challenges of a remote site, such as high ambient temperatures or dust levels.

- Modular and scalable cooling systems allow for flexibility and expansion as the mining operation grows, ensuring long-term sustainability.

Enhancing Network Reliability and Security

The reliability and security of network infrastructure are paramount for the successful remote monitoring and control of ASIC miners. Implementing robust network solutions and adhering to cybersecurity best practices can safeguard mining operations against disruptions and threats.

Strategies for Improving Network Infrastructure and Reliability:

- Deploying redundant network connections and failover systems can ensure continuous connectivity, even in the event of a primary network failure.

- Satellite internet and wireless broadband solutions can provide reliable internet access in remote or underserved areas, expanding the feasibility of remote mining operations.

Best Practices for Securing Remote Mining Operations:

- Implementing end-to-end encryption for data transmission protects sensitive operational data from interception and tampering.

- Regularly updating firmware and software, along with employing advanced threat detection and response systems, can defend against cyberattacks and unauthorized access.

Remote Operating Centers (ROCs)

Remote Operating Centers (ROCs) serve as the nerve center for remote mining operations, centralizing monitoring, control, and decision-making processes. By consolidating these functions, ROCs enhance operational efficiency and facilitate coordinated maintenance efforts.

The Role of ROCs in Centralizing Remote Mining Operations:

- ROCs provide a centralized platform for real-time monitoring and management of multiple remote mining sites, enabling a holistic view of operations.

- Through the integration of advanced monitoring technologies and data analytics, ROCs can optimize maintenance schedules, predict equipment failures, and streamline operational workflows.

Case Studies on Successful ROC Implementations:

- Case studies of mining operations that have successfully implemented ROCs demonstrate the tangible benefits of centralized control, including reduced downtime, improved maintenance efficiency, and increased profitability.

- These success stories highlight the importance of strategic planning, technology integration, and skilled personnel in realizing the full potential of ROCs in remote ASIC maintenance.

By adopting these solutions and best practices, remote mining operations can effectively address the challenges of ASIC maintenance, ensuring the long-term success and sustainability of their mining endeavors.

Future Directions in Remote ASIC Maintenance

As the cryptocurrency mining industry continues to evolve, so too do the strategies and technologies for maintaining ASIC miners, especially in remote operations. The future of remote ASIC maintenance is poised to be shaped by emerging technologies and trends, alongside a growing emphasis on industry collaboration. This section explores the potential advancements and the critical role of partnerships in driving innovation in remote ASIC maintenance.

Emerging Technologies and Trends

The landscape of remote ASIC maintenance is on the cusp of significant transformation, driven by technological advancements that promise to enhance efficiency, reduce downtime, and optimize operations. These innovations offer a glimpse into the future of mining maintenance, where smart, automated systems predominate.

Preview of Upcoming Technological Advancements in ASIC Maintenance:

- Advanced Sensor Technologies: The development of more sophisticated sensors capable of monitoring a wider range of operational parameters will enable more detailed and accurate tracking of ASIC miner performance and health.

- Drone Technology: Drones equipped with cameras and sensors could be used for remote inspection of mining equipment and facilities, providing real-time visual and thermal data without the need for physical access.

The Potential Impact of AI and Machine Learning on Predictive Maintenance:

- Predictive Analytics: AI and machine learning algorithms can analyze vast amounts of operational data to predict potential failures and maintenance needs before they occur, minimizing downtime and extending hardware lifespan.

- Automated Maintenance Scheduling: AI-driven systems could automate the scheduling of maintenance tasks based on predictive analytics, optimizing the timing of maintenance activities to avoid disruptions and improve efficiency.

- Fault Diagnosis: Machine learning models can assist in diagnosing complex issues with ASIC miners, providing maintenance personnel with insights and recommendations for repairs, even from remote locations.

The Role of Industry Collaboration

Innovation in remote ASIC maintenance is not solely the domain of individual companies or operations. Collaborative efforts across the industry are essential for driving forward technological advancements and establishing best practices. Partnerships between mining companies, technology providers, and academic institutions can accelerate the development and adoption of new solutions.

Importance of Partnerships and Collaborations for Innovation:

- Shared Knowledge and Resources: Collaborative projects allow for the pooling of knowledge, expertise, and resources, leading to more efficient research and development efforts.

- Standardization of Practices: Industry-wide collaborations can help establish standardized maintenance practices and protocols, improving the reliability and security of remote mining operations.

Examples of Industry-wide Initiatives for Improving Remote Maintenance:

- Consortiums and Alliances: Formation of consortiums and alliances focused on the development of new technologies for mining operations, such as blockchain for secure data sharing and AI for predictive maintenance.

- Open Innovation Platforms: Launch of open innovation platforms where companies can share challenges and solutions related to ASIC maintenance, fostering a collaborative environment for problem-solving.

- Academic Partnerships: Partnerships with universities and research institutions to explore cutting-edge technologies and their applications in mining, including the use of quantum computing for optimization problems and advanced materials for more durable mining equipment.

The future of remote ASIC maintenance is bright, with emerging technologies and industry collaboration set to redefine how mining operations approach the care and upkeep of their critical hardware. By embracing these advancements and working together, the mining industry can ensure that it remains resilient, efficient, and profitable in the face of evolving challenges.

Conclusion

The journey through the intricacies of remote ASIC maintenance unveils a landscape filled with challenges yet abundant in innovative solutions. From the logistical hurdles of accessing remote sites and the complexities of monitoring and diagnostics from afar to the critical issues of overheating and network reliability, the path to efficient and secure remote mining operations is fraught with obstacles. However, the advent of advanced monitoring technologies, innovative cooling solutions, enhanced network security measures, and the strategic implementation of Remote Operating Centers (ROCs) heralds a new era of possibilities for overcoming these challenges.

The importance of adopting these innovative solutions cannot be overstated. They represent not just a means to address current challenges but a forward-looking approach to ensuring the sustainability and profitability of remote mining operations. As the industry continues to evolve, the integration of emerging technologies such as AI and machine learning for predictive maintenance, alongside the fostering of industry-wide collaborations, will be pivotal in shaping the future of remote ASIC maintenance.

The future of remote mining operations is poised for transformation, driven by technological advancements and a collaborative spirit within the industry. As we stand on the brink of this new horizon, it is imperative for mining operations to embrace these changes, leveraging the latest solutions to enhance their maintenance strategies and secure their place in the next generation of mining.

D-Central Technologies remains at the forefront of this evolution, offering expert ASIC maintenance services and solutions tailored to the unique needs of remote mining operations. Our commitment to innovation and excellence ensures that our clients are equipped with the tools and knowledge necessary to navigate the challenges of remote mining with confidence.

We invite you to visit D-Central Technologies and explore how our services can enhance your mining operations. Moreover, we encourage you to engage with the broader mining community, sharing experiences and insights. Through shared learning and support, we can collectively drive the industry towards a future where remote mining operations are not only viable but thrive on the principles of efficiency, security, and sustainability. Together, let’s embark on this journey towards a brighter future for cryptocurrency mining.

FAQ

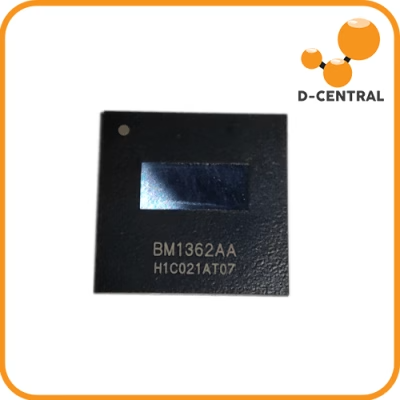

What is an ASIC miner in the context of cryptocurrency mining?

An ASIC miner, or Application-Specific Integrated Circuit miner, is a specialized hardware designed exclusively for mining cryptocurrencies such as Bitcoin. ASIC miners are known for their unparalleled efficiency and speed in processing cryptocurrency transactions, making them the backbone of modern cryptocurrency mining operations.

What are the main challenges of maintaining ASIC miners in remote mining operations?

Maintaining ASIC miners in remote operations presents unique challenges including accessibility and logistic hurdles to remote sites, effective monitoring and diagnostics from afar, managing heat and environmental conditions that can impact hardware efficiency and lifespan, and ensuring network reliability and security to maintain uninterrupted mining activities.

How can advanced monitoring technologies benefit remote ASIC mining operations?

Advanced monitoring technologies, leveraging smart sensors and IoT devices, enable real-time tracking of operational parameters such as temperature, power usage, and hash rate. These technologies facilitate predictive maintenance, helping identify potential failures before they occur, which minimizes downtime and enhances the efficiency of ASIC miners.

What solutions are available for cooling ASIC miners in remote operations?

Solutions for cooling ASIC miners in remote operations include immersion cooling systems, where miners are submerged in a non-conductive liquid for superior cooling efficiency, and advanced air cooling solutions optimized for remote environments. Custom cooling solutions can also be designed to address specific environmental challenges faced by remote sites.

How does enhancing network reliability and security aid remote mining operations?

Improving network infrastructure and reliability through redundant connections and failover systems ensures continuous connectivity for remote monitoring and control of ASIC miners. Implementing cybersecurity best practices, including end-to-end encryption and regular software updates, protects against unauthorized access and cyber threats, securing the mining operations.

What role do emerging technologies play in the future of remote ASIC maintenance?

Emerging technologies such as AI and machine learning for predictive analytics, drone technology for equipment inspection, and advanced sensor technologies are poised to transform remote ASIC maintenance. These technologies enable early detection of potential issues, automated maintenance scheduling, and improved fault diagnosis, enhancing the efficiency and reducing downtime in mining operations.

How can industry collaboration improve remote ASIC maintenance strategies?

Industry collaborations, through consortiums, alliances, and academic partnerships, accelerate the development and adoption of innovative maintenance solutions. Sharing knowledge, resources, and exploring cutting-edge technologies together help establish standardized practices and protocols, improving the reliability and security of remote mining operations.