Description

Tin Tool (BGA Reballing Stencil) for Single Whatsminer Chips

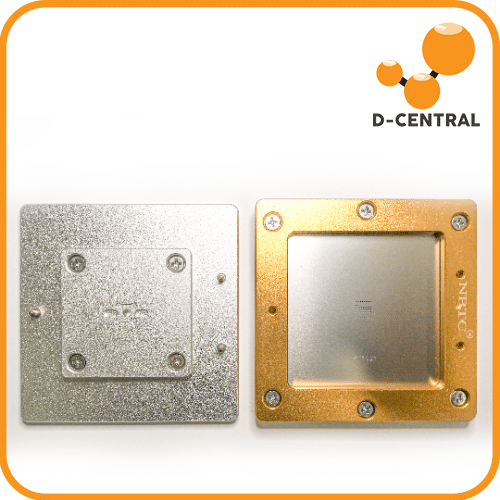

This precision tin tool is a BGA reballing stencil specifically designed for reballing individual Whatsminer ASIC chips, including the KF1921 and KF1930 series. When replacing faulty chips on Whatsminer hashboards, proper solder ball placement is critical for reliable electrical connections. This stencil ensures perfectly aligned, consistent solder bumps on every chip replacement, dramatically improving repair success rates.

Key Specifications

- Type: BGA reballing stencil (tin planting platform)

- Material: Precision-cut stainless steel

- Application: Single-chip reballing

- Compatibility: Whatsminer KF1921, KF1930 ASIC chips

- Construction: High-temperature resistant, maintains dimensional accuracy under heat

Compatible Mining Hardware

This tin tool is designed for chip-level repair on MicroBT Whatsminer hashboards that use KF1921 and KF1930 series ASIC chips, found in miners such as:

- Whatsminer M20 Series: M20, M20S

- Whatsminer M30 Series: M30, M30S, M30S+, M30S++

- Whatsminer M50 Series: M50, M50S

Why You Need This Tool

Chip-level ASIC repair is the most cost-effective way to restore a failing hashboard. When individual ASIC chips fail, the entire hashboard underperforms or goes offline. Replacing the faulty chip requires removing it, cleaning the pads, reballing the new chip with fresh solder bumps, and then reflowing it onto the board.

The reballing step is where this stencil becomes essential. Without a proper stencil, manually applying solder paste to dozens of tiny BGA pads is inconsistent and error-prone. Uneven solder balls lead to cold joints, bridged connections, or open circuits that cause the replacement chip to fail immediately or shortly after repair.

This stencil aligns precisely over the chip, with laser-cut or CNC-machined openings that match the exact BGA pad layout of the KF1921/KF1930 chips. You simply place the chip in the stencil, apply solder paste through the openings, and heat to form perfectly uniform solder balls. The result is a professionally reballed chip ready for reflow onto the hashboard.

Skill Level: Advanced. Requires hot air rework station, BGA stencil holder or jig, solder paste, and chip-level soldering experience.

Reviews

There are no reviews yet.