The Bitcoiner’s Guide to PGP: Securing Your Digital Conversations

In the ever-evolving landscape of digital currencies, the Bitcoin community stands at the forefront of technological innovation and financial freedom.

4479 Desserte Nord Autoroute 440, Laval, QC H7P 6E2

In the intricate world of Bitcoin mining, the efficiency and longevity of mining hardware are paramount to success. Among the critical components of this hardware are hashboards, which play a vital role in processing and generating Bitcoin. However, like any sophisticated electronic equipment, hashboards are susceptible to various issues, with short circuits being among the most detrimental. These electrical faults can not only impair the performance of the mining operation but also lead to significant downtime and, in worst-case scenarios, irreparable damage to the hardware. Thus, the maintenance of hashboards emerges as a crucial task for anyone involved in Bitcoin mining, from individual enthusiasts to large-scale mining farms.

Enter thermal imaging, a revolutionary diagnostic tool that has transformed the way we approach the maintenance and repair of electronic equipment, including hashboards. Thermal imaging technology allows us to visualize heat with an infrared camera, turning an invisible spectrum into a visible picture that highlights temperature differences. This capability is particularly useful in detecting short circuits, which often manifest as hot spots due to the excessive current flow in the affected area. By identifying these hot spots, thermal imaging enables miners to pinpoint short circuits quickly and accurately, often before they escalate into more severe problems. This not only saves time and resources but also extends the operational life of the mining hardware, ensuring that it runs efficiently and reliably.

As we delve deeper into the application of thermal imaging in detecting short circuits on hashboards, it’s important to understand both the technology behind it and the practical steps involved in its use. This introduction serves as the gateway to exploring thermal imaging’s principles, benefits, and methodologies, setting the stage for a comprehensive guide that will equip Bitcoin miners with the knowledge to effectively maintain their hardware and optimize their mining operations.

Thermal imaging, a technology that seems almost futuristic, allows us to see the heat emitted by objects around us, providing a visual representation of temperature differences. At its core, thermal imaging converts infrared radiation (heat) emitted from the surface of objects into visible light. This conversion is possible thanks to thermal cameras, which are equipped with infrared sensors capable of detecting energy in the infrared spectrum. The data collected by these sensors is then processed and displayed as a color-coded image, with different colors representing different temperatures. This image, known as a thermogram, enables the observer to visualize heat even in complete darkness or through obstructions like smoke and fog.

Every object emits infrared energy or heat as part of its natural properties, and the amount of this energy is directly proportional to its temperature. Thermal imaging cameras detect this energy and use it to create a detailed temperature map. The science behind this involves the Planck’s Law, Wien’s Displacement Law, and the Stefan-Boltzmann Law, which together describe the behavior of thermal radiation. By measuring the infrared radiation, thermal cameras can accurately determine the temperature of various objects and components without any physical contact. This capability is particularly useful in electronics, where components are often too small or delicate to be tested with traditional contact-based methods.

The application of thermal imaging in electronics, particularly in the maintenance of hashboards for Bitcoin mining, represents a convergence of advanced technology and practical necessity. By harnessing the power of thermal imaging, miners can ensure the optimal performance of their equipment, reduce the risk of unexpected failures, and maintain the efficiency of their operations in the competitive world of cryptocurrency mining.

Short circuits in hashboards present a critical challenge in the realm of Bitcoin mining, directly impacting both the efficiency of mining operations and the lifespan of the mining hardware. A short circuit occurs when there is an unintended path of low resistance which allows an excessive flow of current through the electrical circuit. This abnormal current flow can lead to overheating, component damage, and in severe cases, complete hashboard failure.

The performance of a hashboard is intricately linked to its electrical integrity. Short circuits can cause significant disruptions, including reduced hashing power, increased error rates, and unexpected shutdowns. These issues not only diminish the effectiveness of the mining operation but also place additional stress on other components, potentially leading to a cascading effect of hardware failures. Furthermore, the excessive heat generated by a short circuit can accelerate the wear and tear of the affected hashboard, drastically reducing its operational lifespan and efficiency.

The early detection of short circuits within hashboards is not merely a technical necessity but also a financially prudent strategy. By identifying and addressing electrical faults at their inception, miners can avoid the more severe consequences that follow unchecked short circuits, including costly repairs and the need for complete hardware replacements.

An analysis of potential savings from early detection reveals a compelling case for the adoption of preventive maintenance practices, such as thermal imaging diagnostics. The cost of repairing a minor fault detected early is significantly lower than the expense involved in replacing an entire hashboard or mining rig. Moreover, by maintaining the hardware in optimal condition, miners can ensure continuous operation, maximizing mining efficiency and profitability.

The cost-effectiveness of early detection extends beyond direct repair and replacement expenses. Operational downtime, during which the mining hardware is not generating revenue, represents a substantial opportunity cost in the fast-paced world of cryptocurrency mining. Early fault detection minimizes downtime, ensuring that mining operations can continue with minimal interruption.

In summary, the significance of detecting short circuits in hashboards lies not only in preserving the functional integrity of the mining hardware but also in safeguarding the efficiency and profitability of the mining operation itself. The adoption of advanced diagnostic tools like thermal imaging for early detection is a strategic investment, offering substantial savings in maintenance, repair, and replacement costs, while also enhancing the overall performance and lifespan of the mining hardware.

Thermal imaging has become an indispensable tool in the arsenal of techniques used for diagnosing issues within hashboards, crucial components in Bitcoin mining rigs. The process involves several key steps, from the initial setup of the thermal imaging camera to the interpretation of the thermal images produced.

Step-by-Step Guide on Using Thermal Imaging Cameras:

Selection Criteria for Thermal Imaging Equipment:

Understanding the thermal images produced during the scan is critical for effective diagnostics. Here’s how to interpret these images:

Through these steps and considerations, thermal imaging provides a powerful means of diagnosing and preventing issues within hashboards, ultimately contributing to the efficiency and longevity of Bitcoin mining operations.

Thermal imaging technology offers a non-invasive, insightful way to diagnose and prevent potential issues in hashboards critical to Bitcoin mining operations. This guide outlines the steps for setting up thermal imaging equipment and conducting a thermal scan, ensuring safety and maximizing the effectiveness of the diagnostic session.

Preparing for a Diagnostic Session: Safety Measures and Best Practices

Detailed Walkthrough of Conducting a Thermal Scan on a Hashboard

Tips for Accurate and Efficient Imaging

By following these guidelines, you can effectively utilize thermal imaging to conduct thorough diagnostics of hashboards, identifying potential issues before they lead to failure. This proactive approach to maintenance can save significant time and resources, ensuring the longevity and efficiency of your Bitcoin mining operations.

While thermal imaging stands out as a powerful diagnostic tool for identifying issues within hashboards, it’s often most effective when used in conjunction with other techniques and tools. This multifaceted approach ensures a comprehensive diagnostic process, enhancing the accuracy of your findings and the effectiveness of subsequent repairs.

How to Use a Multimeter for Preliminary Diagnostics

Before deploying thermal imaging, a multimeter can serve as a first line of investigation, offering a quick, straightforward method to check for electrical continuity and short circuits.

Using a multimeter in these ways provides a quick check that can guide where to focus thermal imaging efforts, making the process more targeted and efficient.

Rubbing Alcohol Method

This technique involves applying a small amount of rubbing alcohol to the surface of the hashboard while it’s powered on. Because alcohol evaporates quickly at room temperature, areas with short circuits or overheating components will cause the alcohol to evaporate more rapidly, visually indicating the problem area. This method is particularly useful for pinpointing hot spots when thermal imaging equipment is not available.

Visual Inspection

Never underestimate the power of a thorough visual inspection. Use a magnifying glass or a microscope to closely examine the hashboard for any signs of physical damage, such as burnt components, melted solder, or discolored traces. Look for bulging or leaking capacitors, which can be precursors to short circuits. Visual inspection can also reveal issues like loose connections or debris causing shorts, which might not be as apparent with other diagnostic methods.

Using a Power Supply with Current Limiting

Another alternative method involves using a bench power supply with adjustable current limiting. By setting a low current limit and applying power directly to the circuit, you can safely induce a short without risking further damage. The power supply’s current limit will engage, preventing excessive current flow, and you can then use a thermal camera or the rubbing alcohol method to locate the heat generated by the short.

Combining these techniques with thermal imaging creates a robust diagnostic toolkit. By starting with a multimeter for preliminary checks, employing visual inspection for obvious physical issues, and using alternative methods like the rubbing alcohol technique for further investigation, you can diagnose and address short circuits and other issues in hashboards with greater accuracy and efficiency. This comprehensive approach not only aids in maintaining the optimal performance of Bitcoin mining operations but also extends the lifespan of the critical hardware involved.

The journey through the intricacies of maintaining hashboards for Bitcoin mining has illuminated the pivotal role of thermal imaging in preempting and diagnosing electrical faults, such as short circuits. This advanced diagnostic tool transcends traditional methods by offering a non-invasive, precise, and visually intuitive means to identify potential issues before they escalate into costly failures.

As we’ve explored, while thermal imaging is a powerful standalone tool, its effectiveness is maximized when used in conjunction with complementary techniques such as multimeter testing, visual inspections, and innovative methods like the rubbing alcohol technique. This multifaceted approach to diagnostics ensures a comprehensive understanding of the health of your mining hardware.

We encourage miners and technicians alike to adopt thermal imaging as a cornerstone of their maintenance strategy. The investment in thermal imaging technology not only safeguards your hardware but also optimizes your mining operation’s productivity and profitability.

For those ready to explore thermal imaging solutions, numerous professional services and products are available that cater to the specific needs of Bitcoin mining. Experts in the field offer consultations, equipment sales, and training sessions to help you integrate thermal imaging into your maintenance routines effectively.

By embracing thermal imaging and its complementary techniques, you’re not just maintaining hardware; you’re investing in the future of your Bitcoin mining operation. The path to enhanced efficiency, reduced downtime, and maximized profitability begins with the adoption of this cutting-edge diagnostic approach.

What is thermal imaging in the context of Bitcoin mining?

Thermal imaging is a diagnostic technique that allows for the visualization of heat on hashboards used in Bitcoin mining. It employs infrared cameras to detect temperature differences, highlighting potential issues such as short circuits, which can prevent costly failures and downtime.

How does thermal imaging detect short circuits in hashboards?

Thermal imaging detects short circuits by visualizing the heat generated by electrical faults. Short circuits typically produce excessive heat, and thermal cameras can pinpoint these hot spots, enabling early detection and intervention.

What are the benefits of using thermal imaging for hashboard maintenance?

The benefits of using thermal imaging for hashboard maintenance include quick detection of potential problems, non-invasive diagnostics, and the ability to conduct inspections without disrupting operation. This technology can save time, protect hardware, and maintain mining efficiency.

Why is detecting short circuits in hashboards important?

Detecting short circuits in hashboards is crucial because such faults can degrade the hashing power, raise error rates, and even lead to hardware failure. Early detection prevents these issues, optimizing the efficiency and lifespan of the mining operation.

What complementary techniques can be used with thermal imaging?

Complementary techniques include using a multimeter for electrical continuity checks, visually inspecting for physical damage, applying rubbing alcohol to identify overheating components quickly, and employing a power supply with current limiting to safely induce and locate short circuits.

How can one get started with using thermal imaging for hashboard diagnostics?

Getting started involves acquiring a thermal imaging camera suitable for electronics diagnostics, understanding its setup and operational guidelines, and following a step-by-step process to scan hashboards. Training and consultations offered by experts in the field can also be beneficial.

What are the key considerations when interpreting thermal images?

Key considerations when interpreting thermal images include identifying unusual hot spots that may indicate short circuits or overheating components, recognizing cold spots as areas of potential concern, and understanding that uniform temperature distribution usually signifies healthy operation.

DISCLAIMER: D-Central Technologies and its associated content, including this blog, do not serve as financial advisors or official investment advisors. The insights and opinions shared here or by any guests featured in our content are provided purely for informational and educational purposes. Such communications should not be interpreted as financial, investment, legal, tax, or any form of specific advice. We are committed to advancing the knowledge and understanding of Bitcoin and its potential impact on society. However, we urge our community to proceed with caution and informed judgment in all related endeavors.

Related Posts

In the ever-evolving landscape of digital currencies, the Bitcoin community stands at the forefront of technological innovation and financial freedom.

Antminer safety is a crucial consideration for anyone involved in cryptocurrency mining. Antminer machines are powerful tools that generate heat,

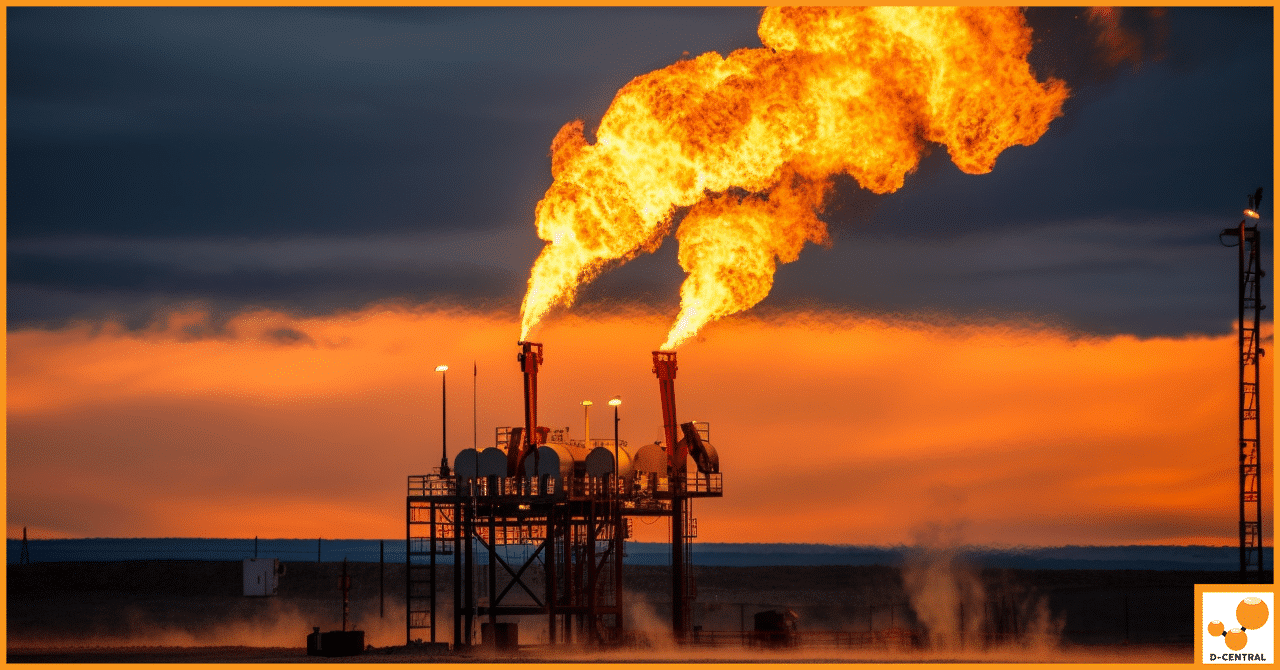

In response to the global climate crisis, two initiatives have been launched that focus on reducing emissions and mitigating the